Our Manufacturing Capabilities

End-to-end precision plastic moulding solutions for water meter and OEM industrial applications.

End-to-end precision plastic moulding solutions for water meter and OEM industrial applications.

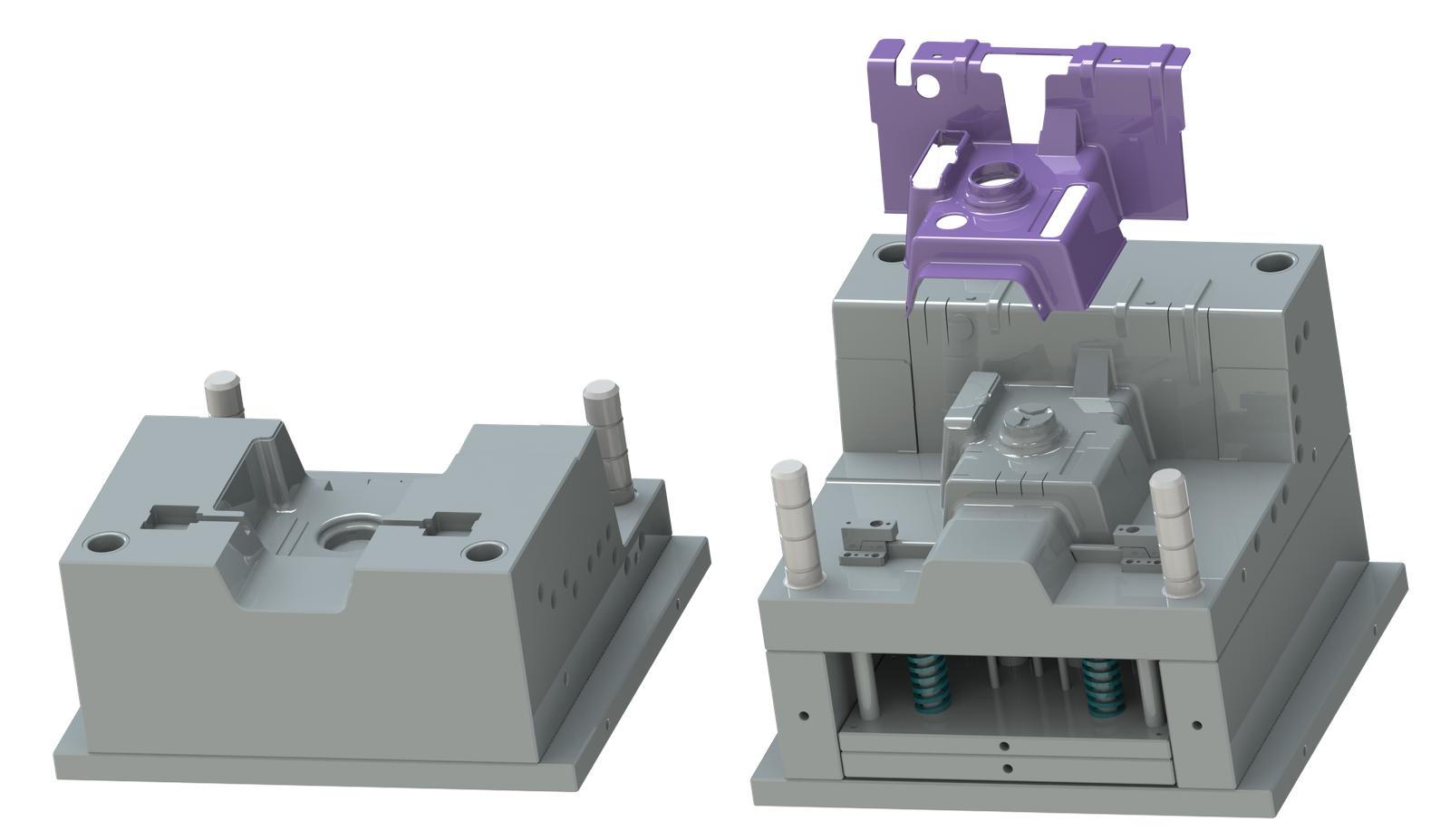

Successful components begin with the right tooling strategy. With decades of experience in mould design and production engineering, our team applies Design for Manufacturing (DFM) principles to ensure that moulds are optimized for accuracy, repeatability, and long-term production stability.

Mould making is a core competency at R-Tek. Since 1992, we have designed and manufactured high-precision moulds that form the foundation of reliable, long-life component production. Our tooling expertise has been built through decades of hands-on experience supporting demanding OEM applications in India and export markets.

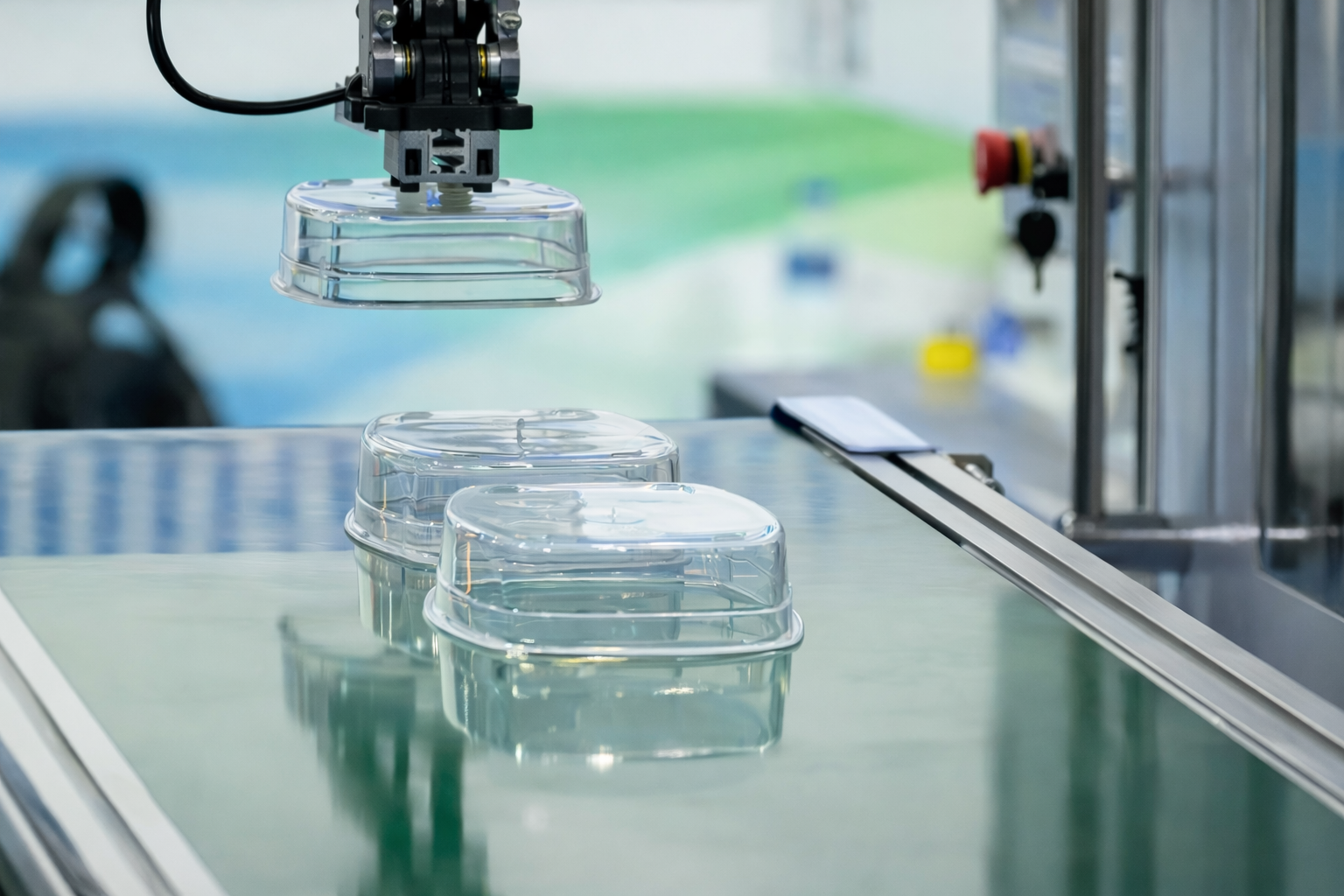

Our production capabilities are centered around precision injection moulding, supported by robust tooling, controlled process parameters, and disciplined quality systems. Each moulding program is established with defined operating windows to ensure dimensional accuracy, material consistency, and repeatable output across extended production runs.

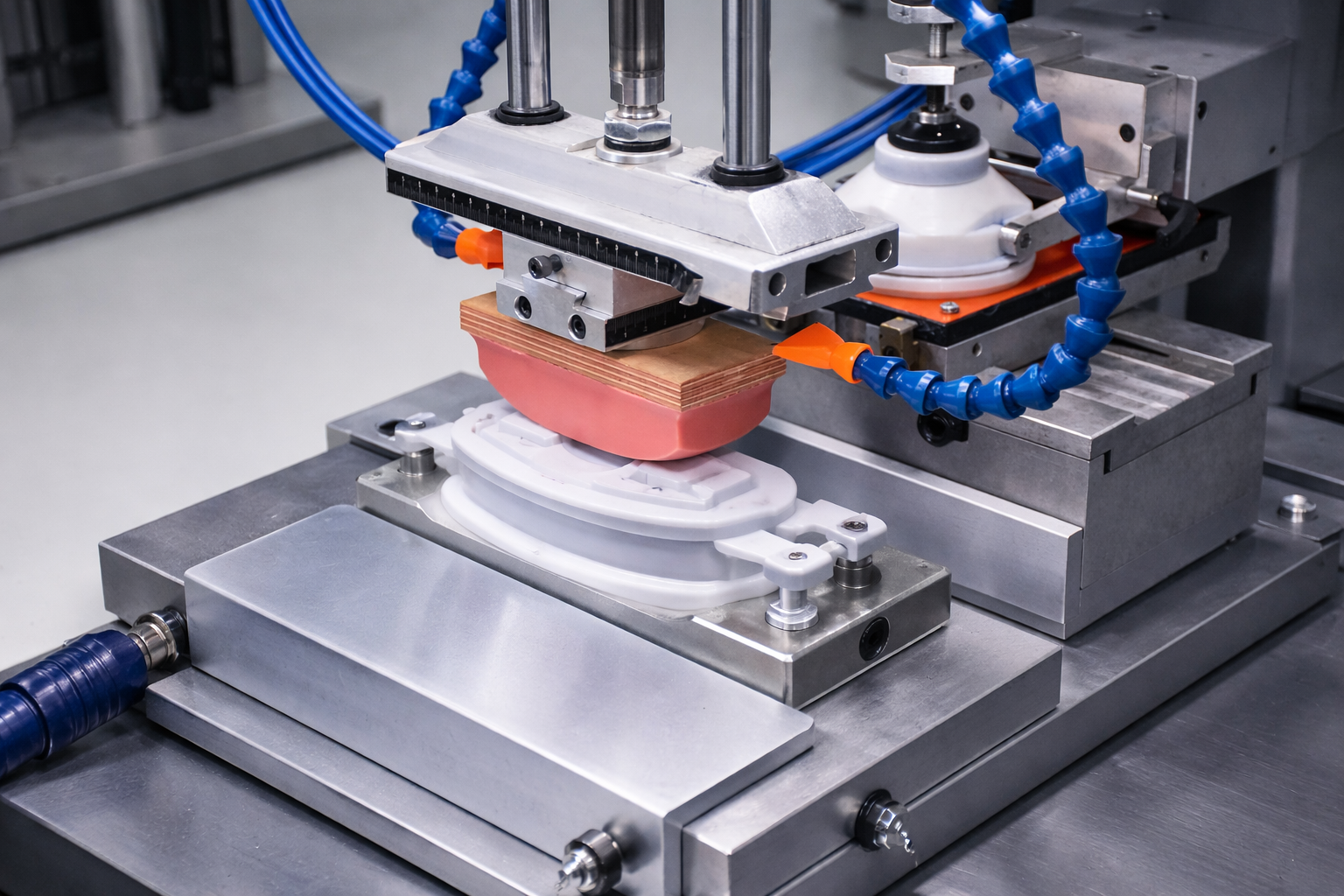

Component identification and traceability are critical in OEM supply programs. Our integrated printing and marking solutions are designed to deliver consistent, durable, and precise markings aligned with production requirements and regulatory needs.

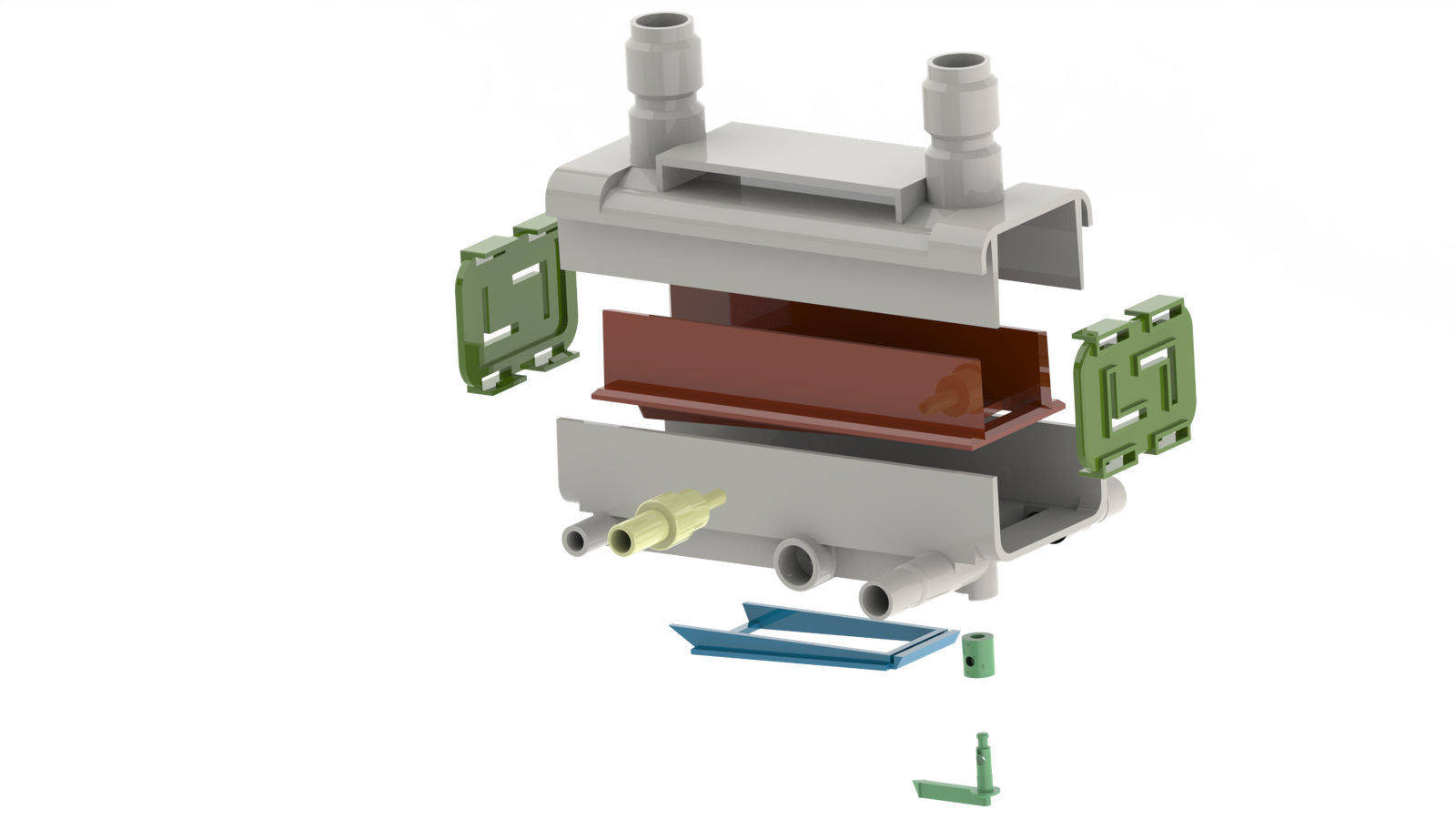

We provide component and sub-assembly solutions that help OEMs simplify their supply chains and reduce in-house handling. Assemblies are designed and executed to ensure functional reliability, dimensional consistency, and ease of integration into customer systems. Our assembly processes are optimized for repeat production, not one-off builds.

Our manufacturing systems are structured to support domestic and export OEM programs with predictable quality, stable processes, and scalable capacity. Quality control is embedded across every stage of production to ensure consistent output over extended production lifecycles.

We work closely with customers to support international supply requirements with disciplined processes and reliable execution.

Our team is ready to support your requirement for precision water meter and plastic moulded components.

Request Capability Statement